Granite sand "money" scene is considerable, profitable

Category: Solution

Release time:2024-07-20

1, China's current demand for sand and gravel aggregate is very large, natural sand resources are scarce in short supply, mechanism sand raw materials are rich and cheap, so stone sand gradually get attention;

2. Granite has excellent texture, close structure, high compressive strength, strong durability, good stability, and its own advantages. In addition, the quality of finished sand products is high and the profit is considerable. Therefore, the general stone sand making will give priority to granite.

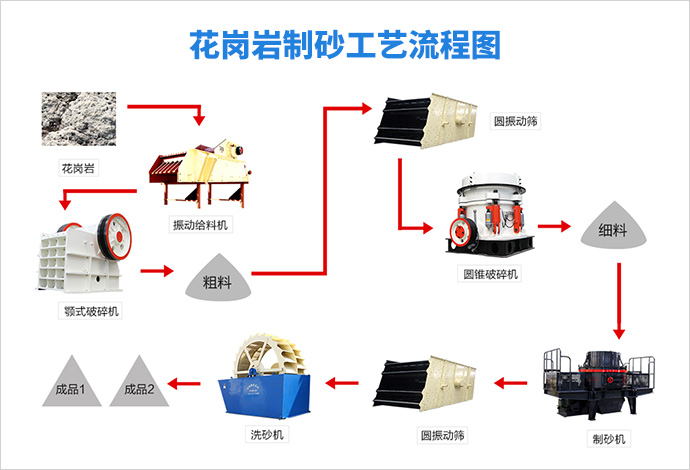

Granite sand making process generally includes gravel, screening, sand making, sand washing and other relief, need to use coarse crushing equipment, medium and fine crushing equipment, screening equipment, sand making equipment, conveying equipment, sand washing equipment. For granite sand, we according to the characteristics of granite itself, recommend the "jaw broken cone broken" scheme configuration.

1. Large petrochemical small, jaw crusher: specially used for crushing large granite raw materials. It has the characteristics of large crushing ratio, wide application range and high hourly capacity. The output can reach 2200 tons per hour. Therefore, jaw crusher is basically selected for coarse crushing equipment of large rocks.

2. Small petrochemical particles and cone crusher: cone crusher is mainly used for medium and fine crushing of materials with high hardness, which is just in line with the characteristics of high hardness of granite. The cone crusher has a large output and can achieve the effect of ultra-fine crushing, but the needle flake content is very large, so sand making machine and sand washing machine need to be configured later to reshape and remove impurities from the stone.

3. Optimize shaping and vertical shaft sand making machine: The sand making principle combining "stone hitting stone" and "stone hitting iron" is adopted to make the finished product grain type very good and the sand yield is also high, which is more than 30% higher than that of traditional sand making equipment. Generally speaking, it is very suitable for granite sand making.

4, clean purification, wheel bucket sand washing machine: its main function is to wash the sand in the soil and sand separation, remove the sand in the confusion of stone powder and other impurities, to achieve the purpose of purification. Wheel bucket sand washing machine sand washing water is less, sand washing water can be recycled, and the rate of fine sand loss is relatively low.

In addition, it is necessary to configure some auxiliary equipment, such as vibrating feeder, vibrating screen, belt conveyor and so on.

Associated Scheme