Cone crusher

Category: Sand and gravel crushing station

Product Details

Equipment Introduction

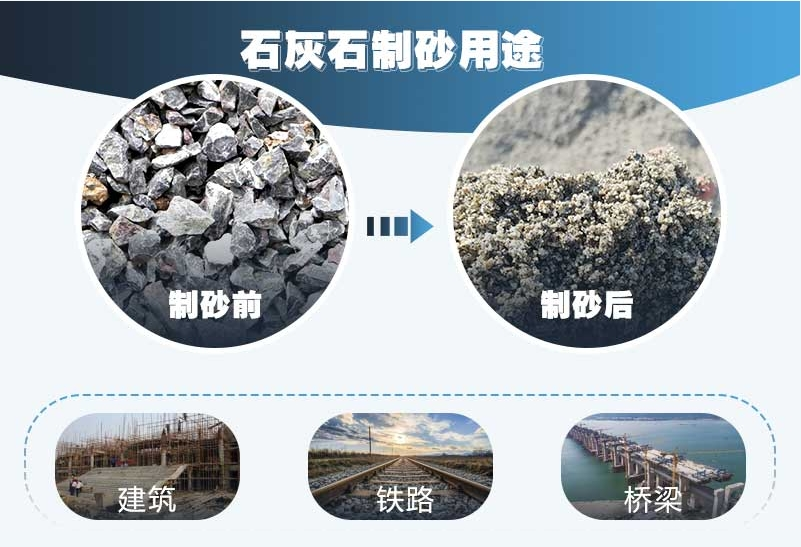

Cone crushers are widely used in metallurgical industry, construction industry, road construction industry, chemical industry and silicic acid industry, and are suitable for crushing various ores and rocks of medium and above. This machine has the characteristics of large crushing force, high efficiency, large processing capacity, low action cost, convenient adjustment and economical use.

Working principle

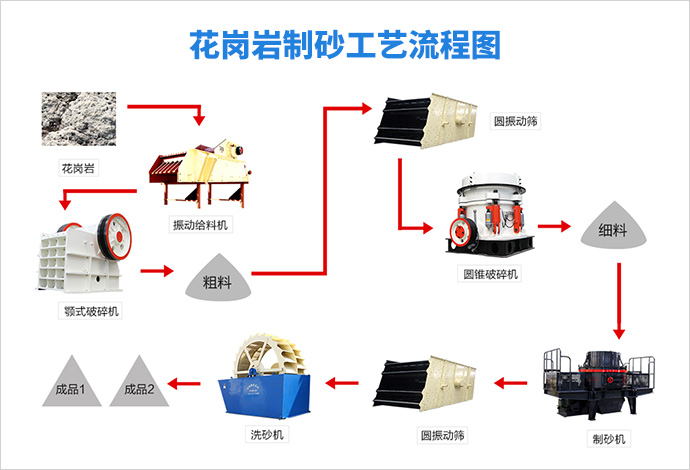

Cone crusher is a modern high-performance crusher based on the principle of laminated crushing and the concept of more crushing and less grinding, which is designed and developed with high swing frequency, optimized cavity type and reasonable stroke. Through the cavity type optimization design and the use of reasonable speed and stroke combination, so that the machine in the case of the same moving cone diameter to do the most work. The second is the use of laminated crushing principle, so that the proportion of the cube in the product is significantly increased. Needle flake stones significantly reduced, more uniform particle size. When broken objects such as iron blocks enter the machine body, the over-iron protection has a fixed return point of the discharge port. After the miscellaneous iron passes through the crushing cavity, the original discharge port can be quickly restored. When working, the motor drives the eccentric sleeve to rotate through the V-belt, large pulley, transmission shaft, pinion and large bevel gear. The axis line of the crushing cone rotates and swings under the force of the eccentric shaft sleeve, so that the surface of the crushing wall is sometimes close to and sometimes away from the surface of the rolling wall, so that the material is continuously impacted in the annular crushing cavity composed of the fixed cone and the moving cone., Squeeze and bend and break. After repeated extrusion, impact and bending, the material is crushed to the required size and discharged through the lower part.

Performance characteristics

1. The machine body is a cast steel structure, and the equipment at the high stress point of the heavy load part has reinforcing ribs.

2. Both ends of the drive shaft are equipped with tapered roller bearings, and the power drive is completed by heavy-duty bevel gears. The bearing seat adopts a skeleton type sealing ring to prevent lubricating oil leakage.

3. The dust cover is floated by the spring placed in the spherical seat and plays an adjusting role during the operation of the machine.

4. Provide spring-type over-iron release protection, which can ensure the normal operation of the crushing system.

5. The structure is novel, unique, simple and reasonable, the operation is balanced, and the operation cost is low.

Related Product recommend

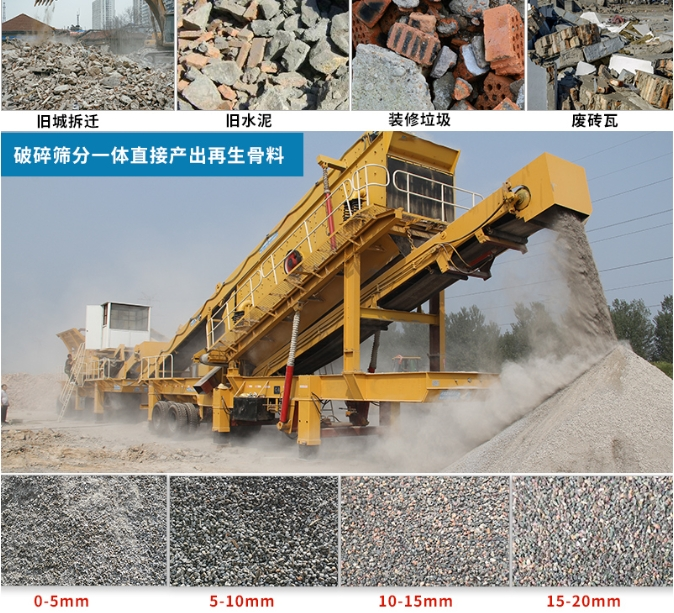

HD80 mobile crushing sand making machine

It combines 3 breakings, makes gravel/sand, multi-functional and time-saving.

HD100 mobile crushing sand making machine

It combines breaking advantages, produces gravel and sand, multi-functional and time-saving.

HD150 mobile crushing sand making machine

It combines 3 breaking advantages, produces both, multi-functional and efficient.

HD200 mobile crushing sand making machine

It integrates 3 breakings, makes gravel & sand, multi-functional & efficient.

HD250 mobile crushing sand making machine

It combines 3 breakings, makes gravel/sand, multi-functional & time-saving.

Mobile high-efficiency anti-attack sand making machine

Sand production rate is 90%, suitable for over 200 minerals crushing.

E-breaking machine (E-type)

Model and parameters of E-breaking machine (E-type).

Impact type sand making machine

Centrifugal impact crusher: wide use, high output, ideal for various materials.

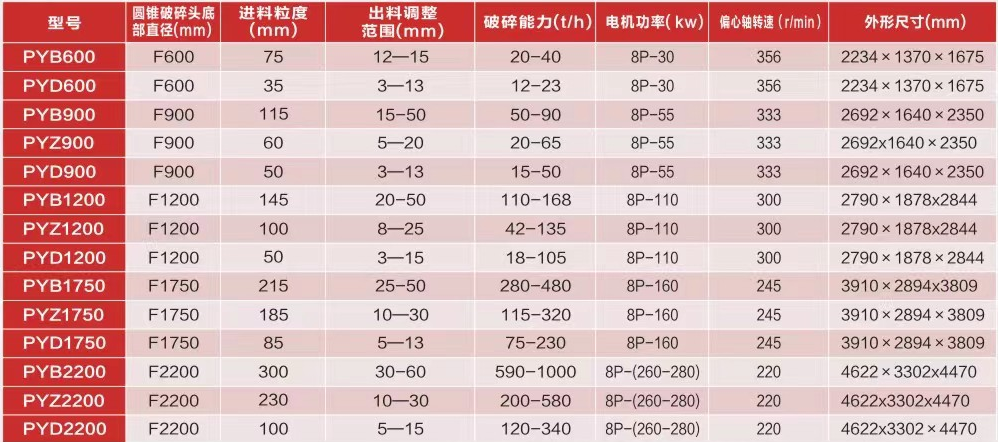

Cone crusher

Cone crushers: widely used, with features of high efficiency and economy.

Vibration sieve sand machine

YA series circular vibrating screen: long sieving line, clear screening.

30 type roller sand screen machine

The working principle of the model 30 roller sand screen is mainly to screen the sand through a number of rotating rollers.

50 type drum type sand sieve machine

Drum screen machine: Screens stones by rotation and jigging effect.

Vibrating feeder

HD series vibration feeder: Simple, high-capacity, low failure rate.

Stone washing machine

This product: Special for high-standard projects, with multiple advantages.

Sand washing machine

Now it's widely used in stone, sand washing and dehydration industries.

Dehydration screen and fine sand recovery integrated machine

Fine sand recovery machine: cleans, recovers sand, boosts economy and reduces pollution.