Limestone sand production line configuration

Category: Solution

Release time:2024-07-22

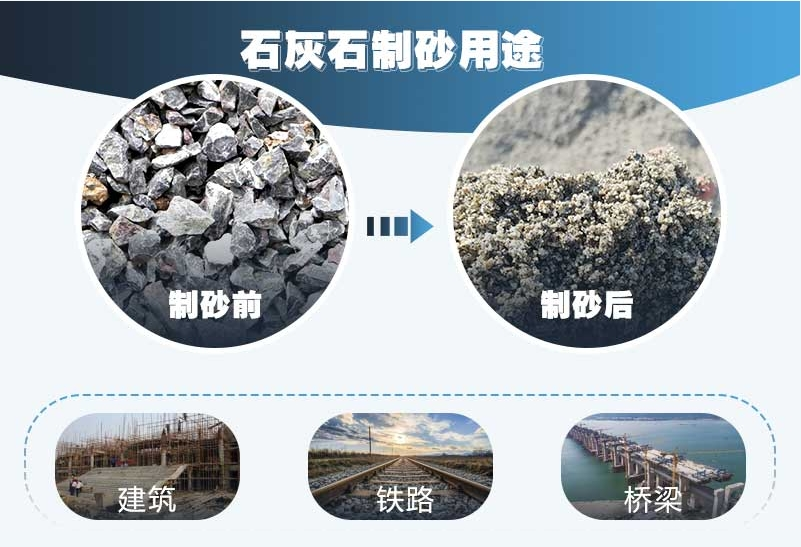

Limestone is a widely distributed sedimentary rock and a widely used ore. Limestone can be made into building sand, can be made into lime, it is also the main raw material of cement, limestone powder or flue gas desulfurization can also play a major role.

When ordinary limestone and cement limestone are used as sand and gravel materials, they have the characteristics of low hardness and easy to be broken, and the consumption of equipment is not very large. However, there is no denying that some limestone has high hardness, so after the wiring money is sampled and tested, the wiring can be made according to the user's capacity demand, specification demand and quality demand after obtaining the hardness.

Limestone sand production line is also a multi-stage crushing method. The first is the coarse crushing process. We often see that the first crushing process in the stock yard is the PE jaw crusher. It can complete the coarse crushing operation with the appropriate feeder model, and can also complete the simple separation of coarse and fine materials. The use of jaw crusher as coarse crushing equipment is also recommend by our Shanghai Jianye Company, because large jaw crusher has large feed inlet, deep cavity crushing, convenient maintenance and low cost, which is suitable for users.

Secondly, the medium and fine crushing link generally adopts a fine jaw crusher or a cone crusher. The main purpose of this link is to further crush the material from the coarse jaw crusher to reach the feed particle size of the limestone sand making machine, namely 40mm or less, so as to ensure the sand making efficiency.

Then there is the fine crushing process. The materials in the medium and fine crushing process are first screened by the screening machine, and the materials that meet the feeding specifications of the sand making machine are screened out, and then enter the sand making machine for shaping and fine crushing. The unqualified second-stage crushing equipment is crushed again. Then the equipment selected by the fine crushing process is the top priority of our sand making equipment-sand making machine. There are many options for sand making machines, but the current impact sand making machine is still the mainstream, which is characterized by high output and good grain shape. The commonly used impact type sand making machine has vertical shaft impact breaking, impact breaking, new sand making machine, composite fine crushing and shaper, etc. The finely crushed material needs to be screened again, and the finished product will enter the finished product area for accumulation or storage in the material tank.

The whole process of sand making is like this. The equipment involved includes vibrating feeder, jaw crusher, fine jaw breaking/cone breaking, sand making machine/impact breaking, vibrating screen and conveyor. In fact, the specific situation of each user is different, the characteristics of the ore are also different, and the requirements for the finished product are also different, so sometimes some other auxiliary equipment is needed, such as environmentally friendly dust removal equipment, sand washing equipment to improve sand quality, winnowing equipment, etc. These are composed of limestone sand making equipment.

Associated Scheme