50 type drum type sand sieve machine

Category: Sieving machine series

Product Details

Product Introduction

Drum screen machine is the traditional screening equipment. After the broken stone enters the drum, the material is screened by the centrifugal force of the drum rotation and the jigging effect. Sieve them out one by one through different mesh screens. Stone materials of different specifications are sieved out and then dropped into the belt conveyor through the funnel and sent to the finished material yard. It has the advantages of simple and reliable structure, stable operation, good sealing, no pollution, low noise, quick net change, fine classification, large sorting ratio, high output, accurate sorting, low failure rate, convenient maintenance, etc., and is especially suitable for sand and gravel. Grading of the yard. Sand screening machine, also known as dry land sand screening ship, is suitable for river, reservoir, coal yard, sand separation equipment. By the hull, shelf, reducer, conveyor belt, rotary screen, engine or motor, composition. This model is simple in structure, economical and applicable, easy to operate. It is divided into drum type sand machine, washing drum type sand sieve machine, vibrating screen type sand sieve machine, etc.

Vibrating sand screening machine is currently more commonly used sand screening equipment, is based on the principle of artificial slope sand screening production, mainly by the motor, reducer sand screening roller, in and out of the material inlet and conveying device and other major parts.

By understanding the structure of the vibrating sand screen machine and the principle of sand screening, the sand screen machine has a deeper understanding and can be better operated.

The roller is a device used to separate the fine sand and gravel of the sand. It is installed on the frame and drives the roller screen to rotate through the action of the motor and the reducer. After the original sand enters the drum, the rotating drum will turn the material over to loosen it, and the sand will be discharged through the rear bottom discharge port of the drum and transported to the designated position by the conveyor belt. The stones in the sand will be discharged from the tail of the drum, which is similar to the principle of artificial sand screening, so the screening rate is very high. The screening capacity of the roller screen sand machine can reach 100-120 cubic meters per hour, which improves the screening efficiency of sand and gravel, and the wet sand can also be screened normally without being affected by the weather.

Scope of application of vibrating sand screening machine

The 1. coal industry is used for the separation of lump coal from pulverized coal and coal washing (an integral part of coal washing machinery).

The sand and gravel are separated from the sand and gravel in the 2. sand and gravel field.

Classification of sub-size stones in 3. quarkyards. As well as the separation of soil and stone powder.

4. the chemical industry, mineral processing industry for the size of the block classification and separation of powdery substances.

The vibrating sand screen machine can screen about 16 tons of sand per hour, which is 16-18 times that of manual labor. The labor efficiency is improved, but the labor intensity is reduced, and it is not restricted by rainy weather, which overcomes the high moisture content of sand and the difficulty of manual screening. The waste of sand is reduced.

Keyword:

Sieving machine series

sand

machine

Previous: 30 type roller sand screen machine

Next: Vibrating feeder

Related Product recommend

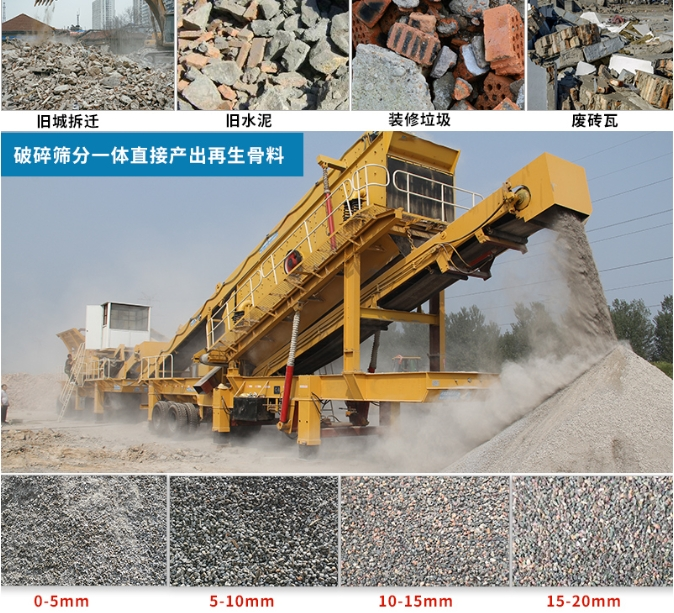

HD80 mobile crushing sand making machine

It combines 3 breakings, makes gravel/sand, multi-functional and time-saving.

HD100 mobile crushing sand making machine

It combines breaking advantages, produces gravel and sand, multi-functional and time-saving.

HD150 mobile crushing sand making machine

It combines 3 breaking advantages, produces both, multi-functional and efficient.

HD200 mobile crushing sand making machine

It integrates 3 breakings, makes gravel & sand, multi-functional & efficient.

HD250 mobile crushing sand making machine

It combines 3 breakings, makes gravel/sand, multi-functional & time-saving.

Mobile high-efficiency anti-attack sand making machine

Sand production rate is 90%, suitable for over 200 minerals crushing.

E-breaking machine (E-type)

Model and parameters of E-breaking machine (E-type).

Impact type sand making machine

Centrifugal impact crusher: wide use, high output, ideal for various materials.

Cone crusher

Cone crushers: widely used, with features of high efficiency and economy.

Vibration sieve sand machine

YA series circular vibrating screen: long sieving line, clear screening.

30 type roller sand screen machine

The working principle of the model 30 roller sand screen is mainly to screen the sand through a number of rotating rollers.

50 type drum type sand sieve machine

Drum screen machine: Screens stones by rotation and jigging effect.

Vibrating feeder

HD series vibration feeder: Simple, high-capacity, low failure rate.

Stone washing machine

This product: Special for high-standard projects, with multiple advantages.

Sand washing machine

Now it's widely used in stone, sand washing and dehydration industries.

Dehydration screen and fine sand recovery integrated machine

Fine sand recovery machine: cleans, recovers sand, boosts economy and reduces pollution.