Ore crushing production line equipment

Category: Classic Case

Release time:2024-07-20

Ore crushing production line equipment can be used for hard limestone, granite, basalt, river pebbles, pebbles, slag and other materials of aggregate and artificial sand making operations, suitable for hydropower, high-speed rail construction, building materials, highways, urban construction, cultural landscape, embankment flood control belt construction and other widely used.

Ore crushing production line equipment uses and advantages

Ore crushing production line equipment can be used for hard limestone, granite, basalt, river pebbles, pebbles, slag and other materials of aggregate and artificial sand making operations, suitable for hydropower, high-speed rail construction, building materials, highways, urban construction, cultural landscape, embankment flood control belt construction and other widely used.

High degree of automation, low operating costs, high crushing rate, the production of stones with uniform particle size, good grain shape, energy saving, large output, less pollution, easy maintenance, the production of ore in line with the national construction sand standards, uniform product size, good grain shape, level coordination.

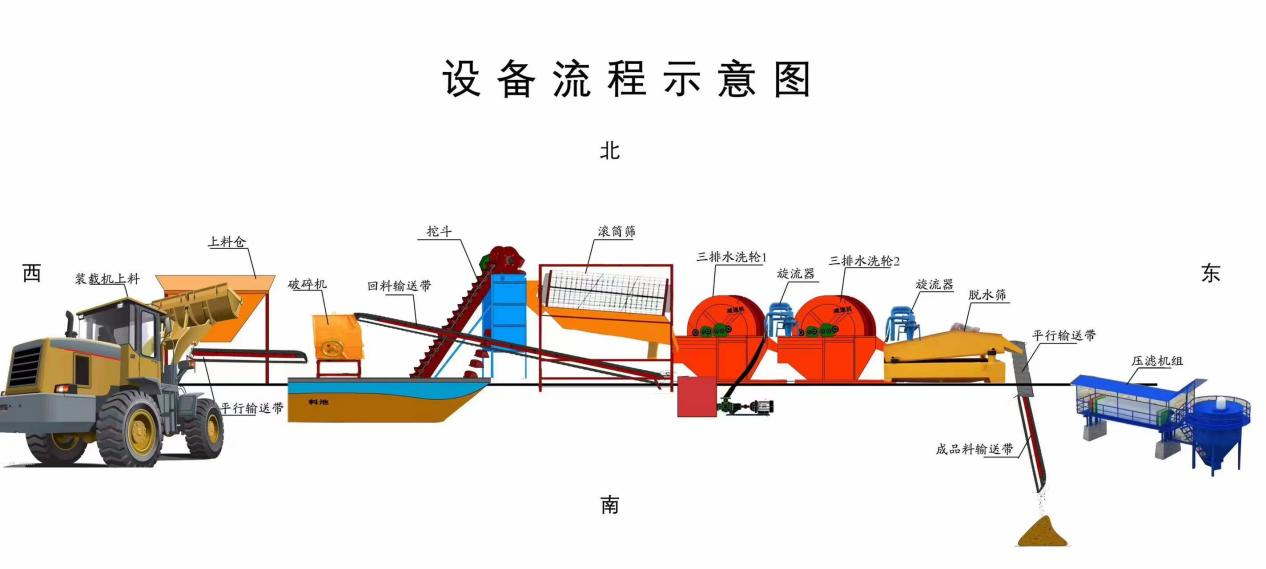

Ore production line process

The stone is evenly fed to the coarse crusher-jaw crusher by the feeder for preliminary crushing, then the produced coarse material is transported by the belt conveyor to the impact crusher for further crushing, the finely crushed stone is fed into the vibrating screen to screen out stones of different specifications, and the stone return that does not meet the particle size requirement is fed into the impact crusher for further crushing. The large stone is uniformly sent to the jaw crusher by the vibrating feeder for coarse crushing, and the roughly crushed stone is sent to the impact crusher by the belt conveyor for further crushing; the finely crushed stone is sent to the vibrating screen by the belt conveyor for screening, and several stones of different specifications are screened out. The stones that meet the particle size requirements are sent to the finished material pile by the finished product belt conveyor; the stones that do not meet the particle size requirements are returned by the belt conveyor to the impact crusher for re-crushing, form a closed loop multiple times. The particle size of the finished product can be combined and graded according to the needs of users. In order to protect the environment, auxiliary dust removal equipment can be equipped.

My company produces a full set of ore production line equipment, to provide you with a comprehensive. This production line is composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen and belt conveyor. According to different process requirements, various types of equipment are combined to meet the different process requirements of the customer's stone production line.

key word:

Associated Scheme